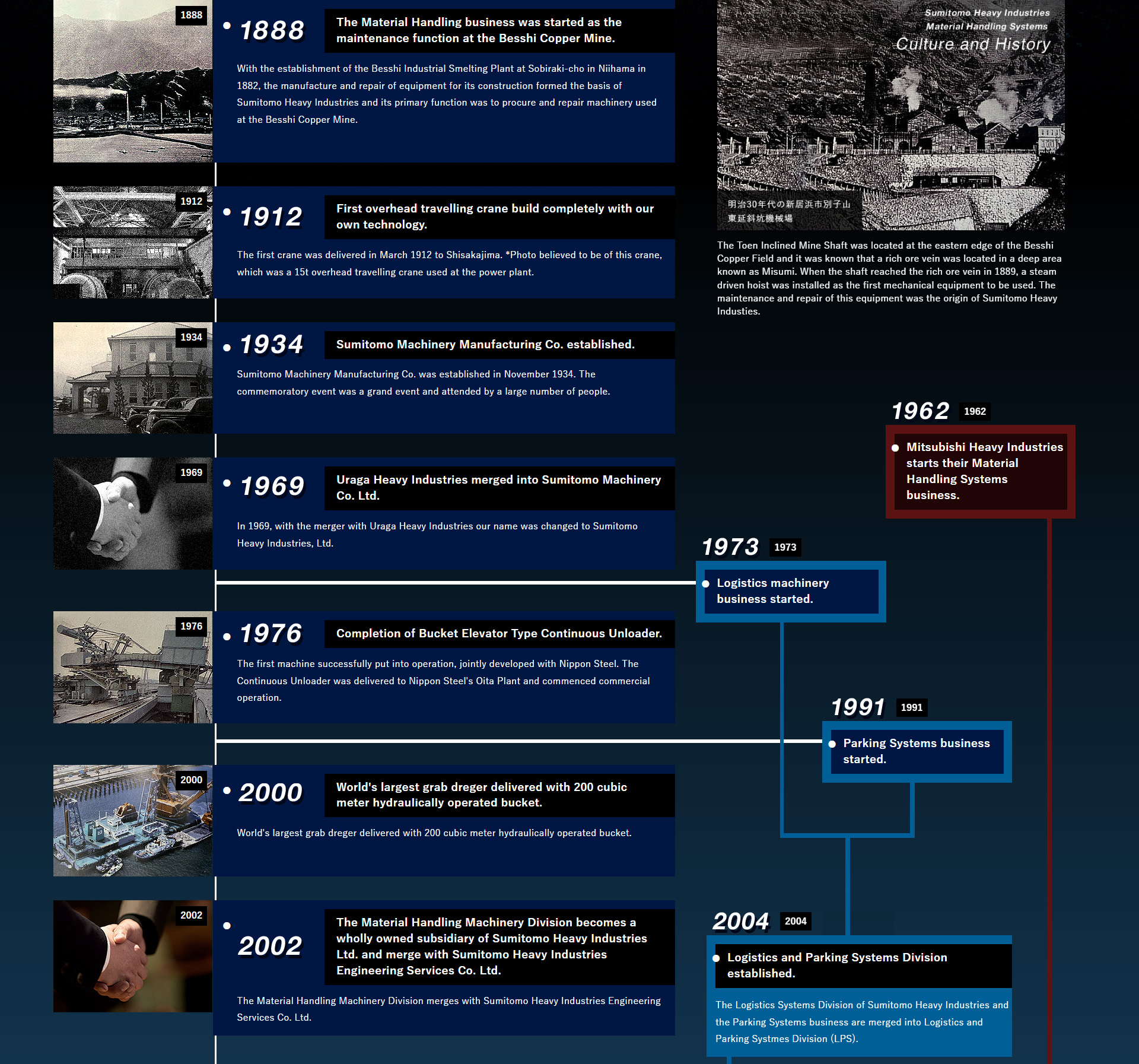

HISTORY

The light that illuminates our business.

For three centuries since our founding, we have continued to illuminate our business.

We have been a pioneering business committed to solving the social problems of the times.

To realize these goals ourselves with strong conviction and pride

To keep the light that enables our effort to solve problems, shining, our technology, teamwork and resolve to build a better future, developed through our long history will serve as a base to light the way to the next era.

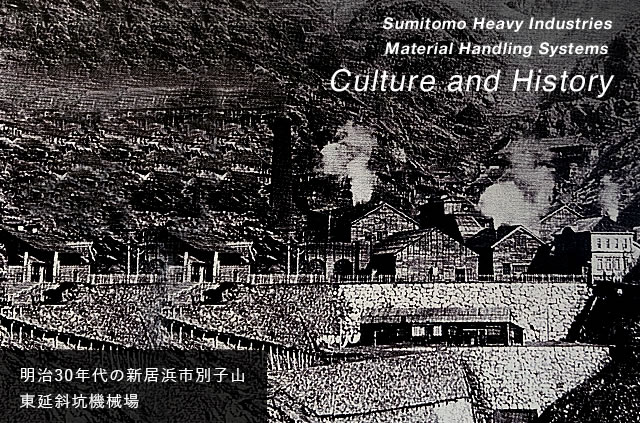

The Toen Inclined Mine Shaft was located at the eastern edge of the Besshi Copper Field and it was known that a rich ore vein was located in a deep area known as Misumi. When the shaft reached the rich ore vein in 1889, a steam driven hoist was installed as the first mechanical equipment to be used. The maintenance and repair of this equipment was the origin of Sumitomo Heavy Industies.

OPEN

With the establishment of the Besshi Industrial Smelting Plant at Sobiraki-cho in Niihama in 1882, the manufacture and repair of equipment for its construction formed the basis of Sumitomo Heavy Industries and its primary function was to procure and repair machinery used at the Besshi Copper Mine.

OPEN

The first crane was delivered in March 1912 to Shisakajima. *Photo believed to be of this crane, which was a 15t overhead travelling crane used at the power plant.

OPEN

Sumitomo Machinery Manufacturing Co. was established in November 1934. The commemoratory event was a grand event and attended by a large number of people.

OPEN

In 1969, with the merger with Uraga Heavy Industries our name was changed to Sumitomo Heavy Industries, Ltd.

OPEN

The first machine successfully put into operation, jointly developed with Nippon Steel. The Continuous Unloader was delivered to Nippon Steel's Oita Plant and commenced commercial operation.

OPEN

World's largest grab dreger delivered with 200 cubic meter hydraulically operated bucket.

OPEN

The Material Handling Machinery Division merges with Sumitomo Heavy Industries Engineering Services Co. Ltd.

OPEN

The Logistics Systems Division of Sumitomo Heavy Industries and the Parking Systems business are merged into Logistics and Parking Systmes Division (LPS).

OPEN

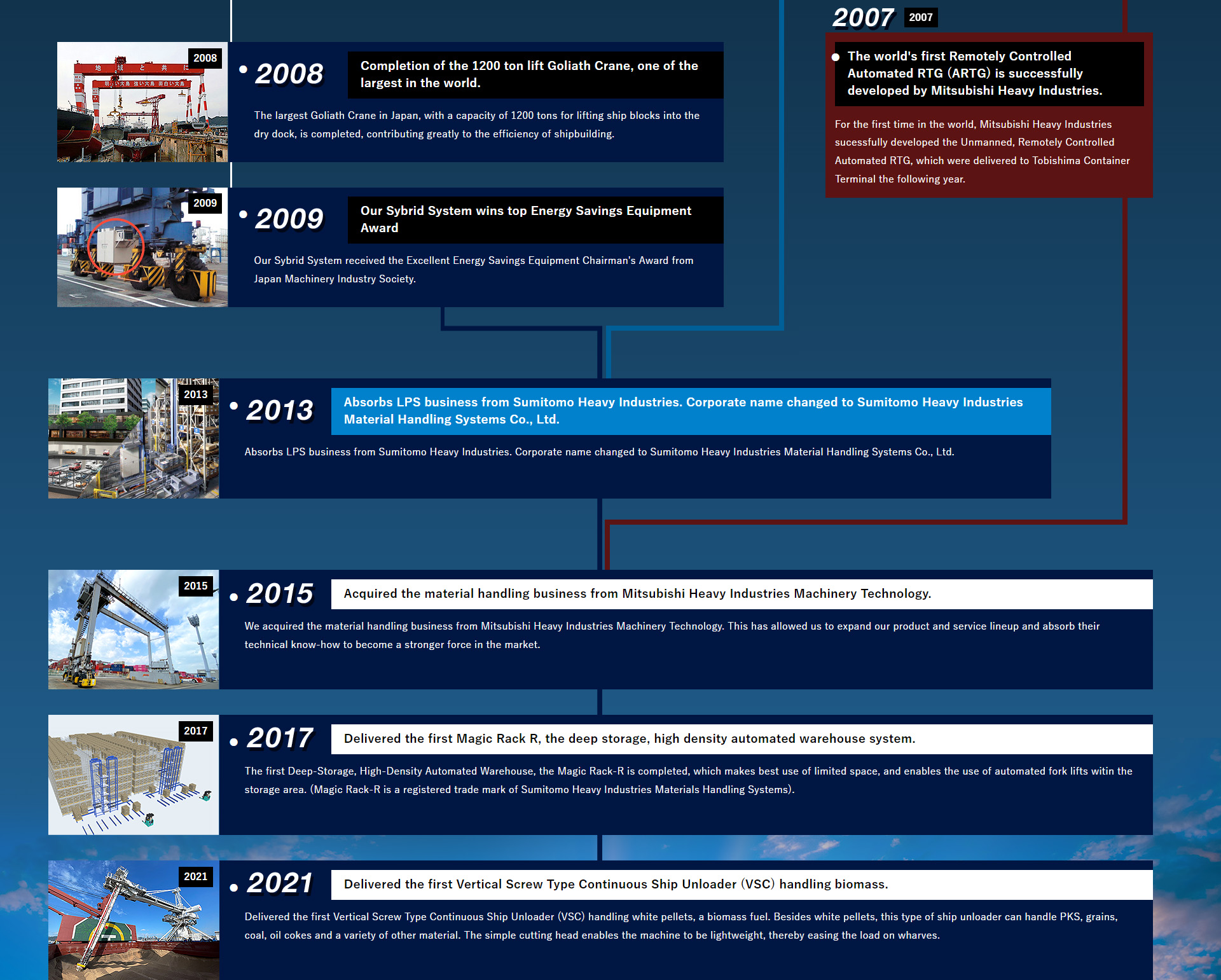

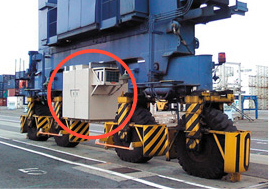

For the first time in the world, Mitsubishi Heavy Industries sucessfully developed the Unmanned, Remotely Controlled Automated RTG, which were delivered to Tobishima Container Terminal the following year.

OPEN

The largest Goliath Crane in Japan, with a capacity of 1200 tons for lifting ship blocks into the dry dock, is completed, contributing greatly to the efficiency of shipbuilding.

OPEN

Our Sybrid System received the Excellent Energy Savings Equipment Chairman's Award from Japan Machinery Industry Society.

OPEN

Absorbs LPS business from Sumitomo Heavy Industries. Corporate name changed to Sumitomo Heavy Industries Material Handling Systems Co., Ltd.

OPEN

We acquired the material handling business from Mitsubishi Heavy Industries Machinery Technology. This has allowed us to expand our product and service lineup and absorb their technical know-how to become a stronger force in the market.

OPEN

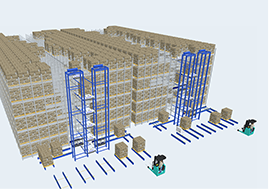

The first Deep-Storage, High-Density Automated Warehouse, the Magic Rack-R is completed, which makes best use of limited space, and enables the use of automated fork lifts witin the storage area. (Magic Rack-R is a registered trade mark of Sumitomo Heavy Industries Materials Handling Systems).

OPEN

Delivered the first Vertical Screw Type Continuous Ship Unloader (VSC) handling white pellets, a biomass fuel. Besides white pellets, this type of ship unloader can handle PKS, grains, coal, oil cokes and a variety of other material. The simple cutting head enables the machine to be lightweight, thereby easing the load on wharves.