Logistics System TECHNOLOGY

Magic Rack for Multiple Types of Pallets to Solve Labor and Space Shortages

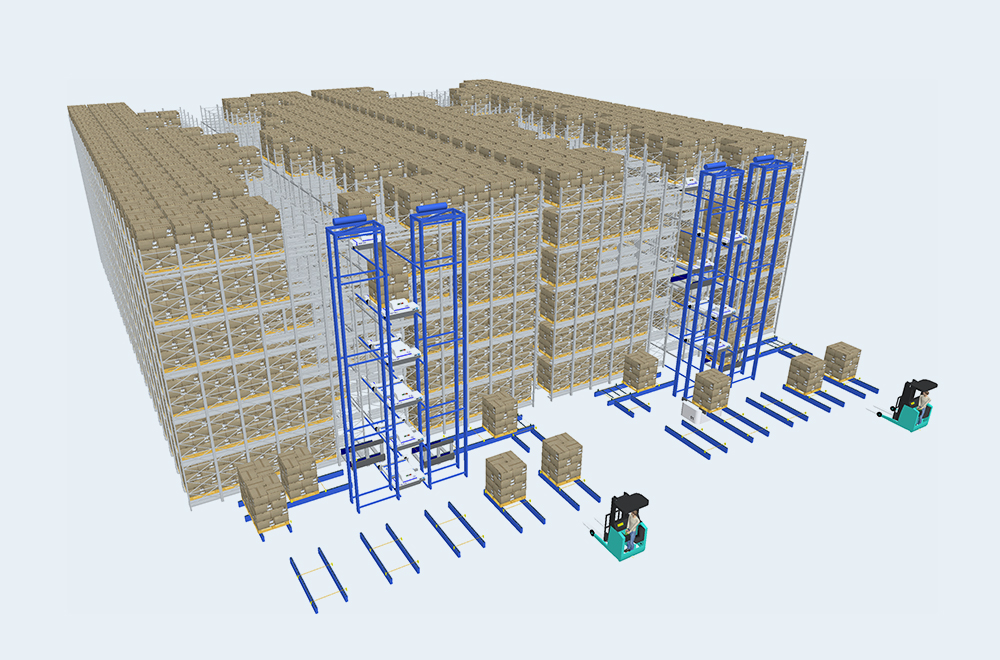

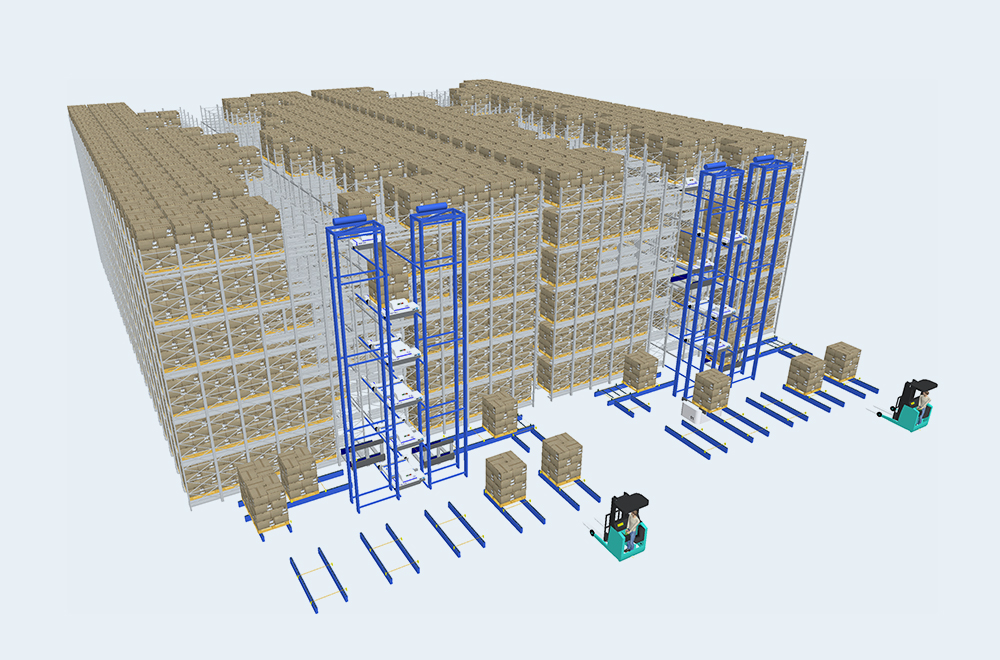

Magic Rack with Significant Storage Capacity and Space Efficiency

We will build an automated warehouse system that optimizes space utilization and operation with a significant storage capacity using deep storage methods. By reducing the need for manual pallet handling, we will also reform the working methods of forklift operators.

- KEYWORD

-

- #Automated Warehouse System

- #Efficiency and Automation

- #Solving Labor Shortages

- #Space Utilization

- #Work Style Reform

Adaptable to various types of supply chain

The pallet sizes that could be handled initially were 1100 (L) x 1100 (W) mm, which is widely used in the logistics industry, and 1100 (L) x 900 (W) mm, which is optimized for the beverage industry. However, as the name recognition has increased, we have received more requests for the introduction of Magic Rack from a wide range of customers, including packaging material and container manufacturers and the chemical industry. Packaging material and container manufacturers requested pallet sizes of 1200 (L) x 1300 (W) mm, and the chemical industry mainly required pallet sizes of 1100 (L) x 1400 (W) mm. Magic Rack's mission is to contribute to resolving labor shortages in the supply chains of a wide range of industries, and we have taken this as our next challenge. We have expanded the variations to a maximum of 1200 (L) x 1400 (W) mm, and have expanded the system so that multiple pallet sizes can be stored and transported within one system. This has increased the coverage rate of pallet sizes in circulation by 18%, from 80% to 98%, and increased the weight from the previous 1000 kg to 1100 kg.

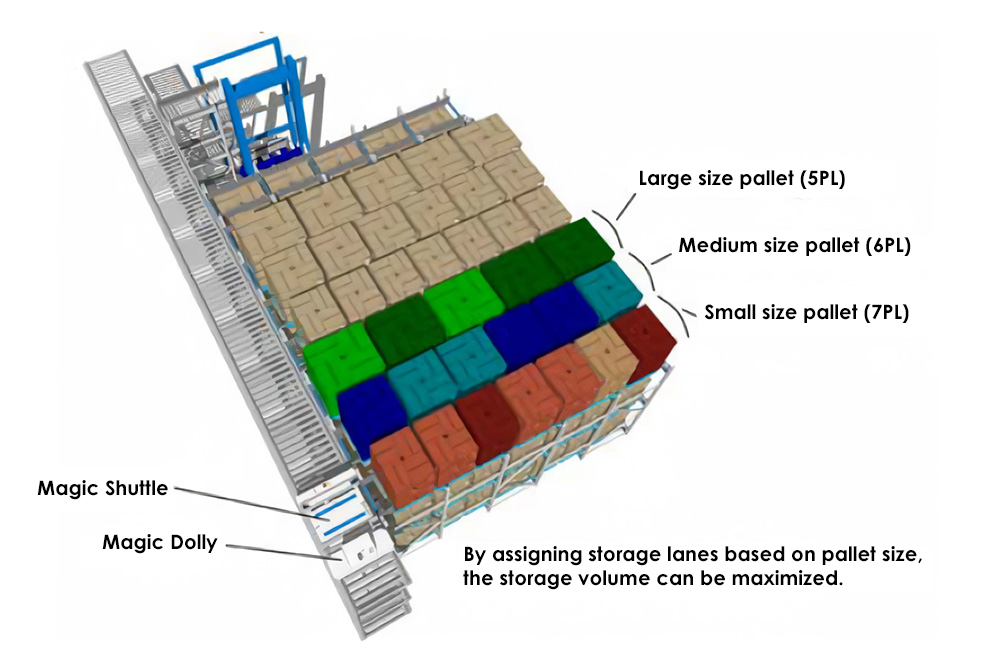

Pursuit of pallet diversity and safety

In order to store multiple types of pallet sizes, the storage position that differs depending on the pallet width is handled by dynamically controlling the pallet size information at the time of storage and the algorithm of the magic shuttle's stopping position at the time of storage (see figure). In addition, while strengthening the machine and rack structure to accommodate the increase in pallet size and weight, each device has been improved so as not to lose its high density characteristic, and it is possible to store multiple pallet sizes while maintaining the concept of "storing 1.5 m load in three layers on a 5.5 m floor height". In an era in which the labor population is decreasing more and more and labor shortages can determine the fate of the customer's business itself, we will pursue the excess of "flexibility and lineup expansion" in the automation of pallet storage and loading and unloading work, and by continuing to apply the latest technology, we will continue to provide products that support work style reform in logistics sites and contribute to increasing value for our customers.

MENU