Material Handling System TECHNOLOGY

Our Own Technology for Vertical Screw Type Continuous Unloaders

and Examples of Upgrading

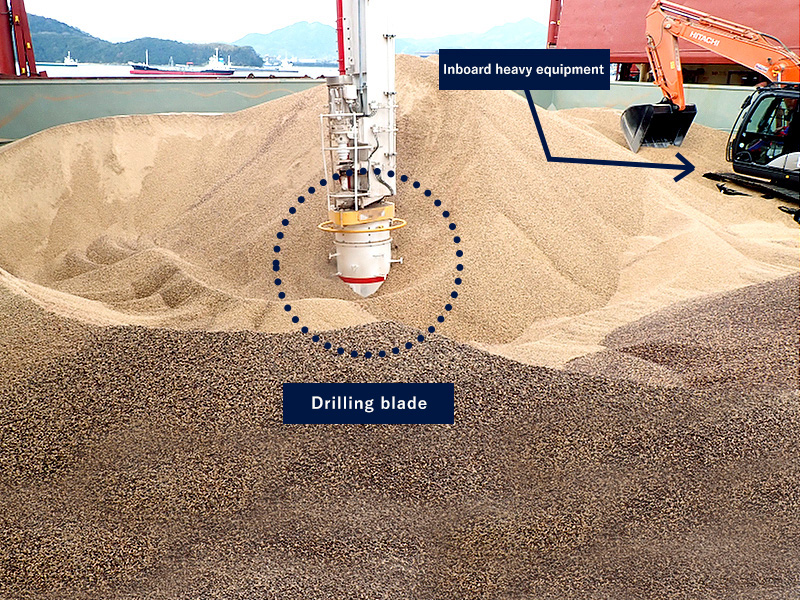

Vertical Screw Conveyor Unloader

Capable of handling a large range of materials including biomass fuels best suited for environmental protection and sustainable development.

We have a long track record with our Vertical Screw Type Continuous Unloaders capable of handling a wide variety of materials. It is especially suited for handling white pellets and similar biomass fuels which are valuable for renewable energy generation. The unloader can maintain a steady digging depth to facilitate simplified operation and increased efficiency. Further, the simple digging mechanism keeps machine weight low for less loading on the wharf.

- KEYWORD

-

- #Cost Reduction

- #Sustainability

Example of Design Upgrade: Screw Column Design

Optimization of flow of biomass pellets in the screw column using simulation by the RMD (Renormalized Molecular Dynamics) menthod.

Example of Design Upgrade: Inlet Control for Biomass Pellets

Biomass pellets can stick to hatch walls to form steep walls which can then collapse to disrupt unloading operations. To enable smooth and stabe unloading we use a number of controls to minimize these risks:

▶Control the speed of the digging blades to minimize

collapse.

▶Maintain digging depth to ensure steady unloading rate.

MENU